Maka robots ụlọ ọrụ mmepụta ihe, ihe eji eme ihe bụ otu n'ime ngwa kachasị mkpa na njikwa ha.Dị ka ụdị ngwá ọrụ na-arụ ọrụ nke nwere ike dịgasị iche iche, ịrụcha ọrụ nke robot mmepụta ihe na-adabere kpọmkwem na usoro nkwụsị.Ya mere, a ga-emepụta usoro nkedo na njedebe nke robot dịka ọrụ arụ ọrụ na ihe ndị chọrọ na gburugburu ebe ọrụ si dị.Nke a na-eduga n'ichepụta ụdị nhazi nke usoro ihe nkedo.

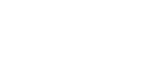

Ọgụgụ 1 Mmekọrịta dị n'etiti ihe, atụmatụ na paramita nke njedebe njedebe Ọtụtụ usoro nchikota igwe bụ ụdị mkpịsị aka abụọ, nke enwere ike kewaa n'ime: ụdị rotary na ụdị ntụgharị dịka usoro mmegharị nke mkpịsị aka;Enwere ike kewaa ụzọ mgbochi dị iche iche n'ime nkwado dị n'ime Dị ka njirimara nhazi si dị, enwere ike kewaa ya n'ụdị pneumatic, ụdị eletriki, ụdị hydraulic na usoro ha jikọtara ọnụ.

Usoro njigide ngwụcha pneumatic

Isi iyi nke ikuku pneumatic na-adaba adaba iji nweta, ọsọ ọsọ na-eme ngwa ngwa, onye na-arụ ọrụ na-enweghị mmetọ, na mmiri mmiri dị mma karịa usoro hydraulic, nkwụsị nrụgide dị ntakịrị, ọ dịkwa mma maka ogologo oge. njikwa anya.Ndị a bụ ọtụtụ manipulators pneumatic:

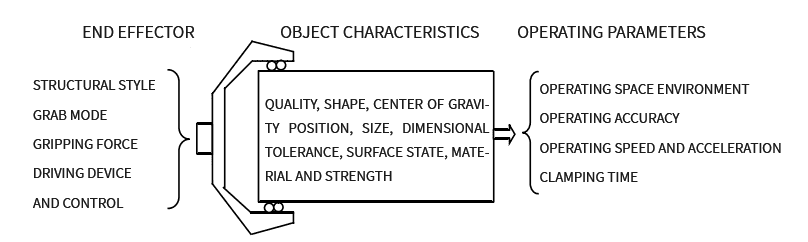

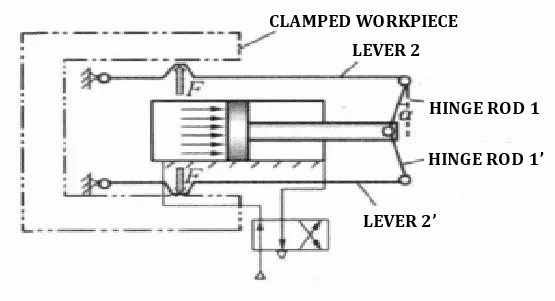

1. Rotary njikọ lever-ụdị clamping usoro Mkpịsị aka nke ngwaọrụ a (dị ka V-shaped mkpịsị aka, curved mkpịsị aka) na-obere na clamping usoro site bolts, nke dị mfe karịa dochie, n'ihi ya, ọ nwere ike budata gbasaa ngwa nke usoro clamping.

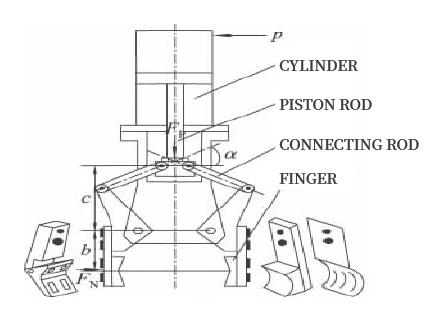

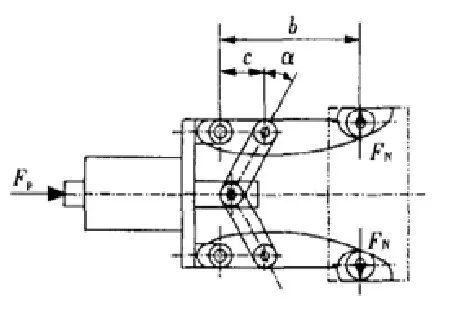

Ọgụgụ 2 Rotary njikọ lever ụdị clamping usoro Ọdịdị 2. Mkpịrị kwụ ọtọ ụdị okpukpu abụọ cylinder nsụgharị clamping usoro A na-etinyekarị njedebe mkpịsị aka nke usoro njide a na mkpanaka kwụ ọtọ nke nwere mkpịsị mkpịsị aka na-agbago oche.Mgbe a na-eji oghere mkpanaka abụọ nke cylinder na-eme ihe abụọ, piston ga-eji nwayọọ nwayọọ na-aga n'etiti ruo mgbe a na-ejikọta ya.

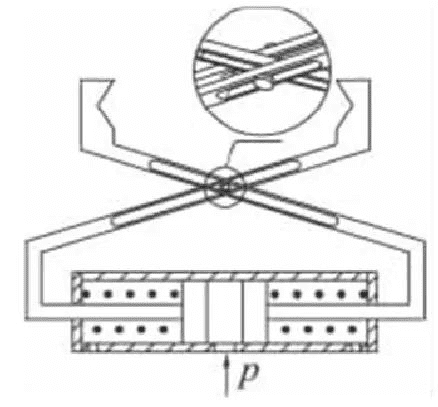

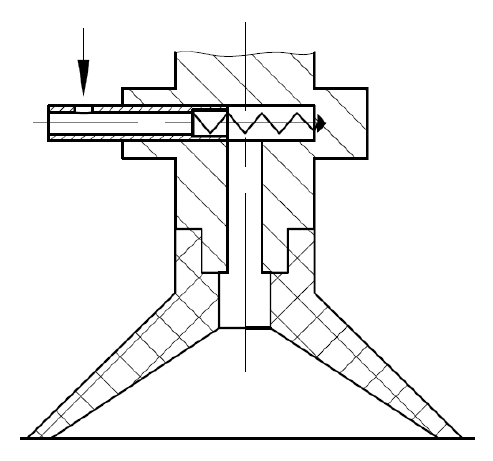

Onyonyo 3 Eserese nhazi nke usoro ntughari ntughari ogologo-ogidi abụọ-cylinder 3. Usoro njiko njikọ cross-ụdị okpukpu abụọ-cylinder na-ejikarị cylinder eme ihe na mkpịsị aka ụdị obe.Mgbe gas na-abanye n'etiti oghere nke cylinder ahụ, ọ ga-agbanye pistons abụọ ka ọ gaa n'akụkụ abụọ ahụ, si otú a na-ebugharị mkpanaka njikọ ka ọ gaa, na njedebe mkpịsị aka gafere ga-edozi ọrụ ahụ;ma ọ bụrụ na ọ dịghị ikuku na-abanye n'etiti oghere, piston ga-n'okpuru edinam nke mmiri na-akpali Tọgharia, na ofu workpiece ga-ahapụ.

Onyonyo 4. Ọdịdị nke cross-ụdị abụọ-cylinder nsụgharị clamping usoro mkpakọ nwere mgbidi nwere oghere ime.Mgbe clamping usoro esetịpụ workpiece, iji hụ na ọ nwere ike na-positioned were were na n'ime oghere, na-emekarị 3 mkpịsị aka arụnyere.

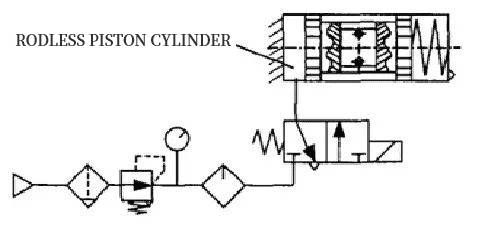

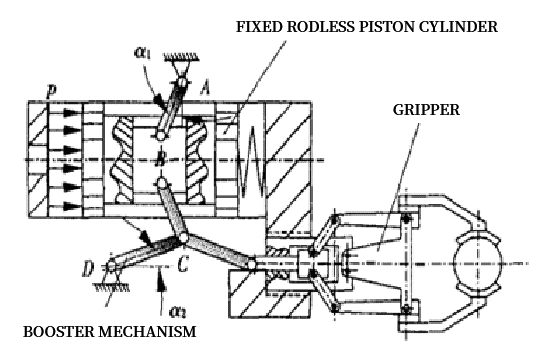

Ọgụgụ 5 Ihe eserese nke usoro ihe nchikota nke lever-ụdị clamping nke mkpara nkwado dị n'ime 5. Usoro nkwalite na-ebugharị site na piston cylinder na-enweghị eriri na-arụ ọrụ n'okpuru ọrụ nke ike mmiri, a na-enweta ntụgharị site na valvụ solenoid nke abụọ dị n'akụkụ atọ.

Onyonyo 6 Sistemụ pneumatic nke piston cylinder enweghị mkpali A na-etinye ihe mmịfe mgbanwe n'ọnọdụ radial nke piston nke piston cylinder na-enweghị mkpanaka, na mkpanaka abụọ na-agbanye n'ụzọ symmetrically na nsọtụ abụọ nke ihe mmịfe ahụ.Ọ bụrụ na ike mpụga na-arụ ọrụ na piston, piston ga-eme Ọ ga-aga n'aka ekpe na aka nri, si otú ahụ na-akpali ihe mmịfe ahụ ka ọ gaa n'elu na ala.Mgbe a na-ejikọta usoro ahụ, ebe mgbanaka B ga-emegharị okirikiri gburugburu ebe A, na mmegharị elu na ala nke ihe mmịfe ahụ nwere ike ịgbakwunye ogo nke nnwere onwe, na oscillation nke isi C na-anọchi anya oscillation nke cylinder dum. ngọngọ.

Ọgụgụ 7 Usoro na-akwalite ike nke piston cylinder na-enweghị mkpanaka na-ebugharị

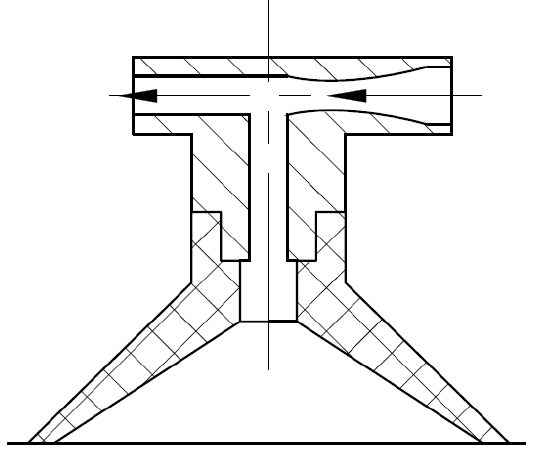

Mgbe valvụ nchịkwa ntụziaka nke ikuku abịakọrọ dị n'aka ekpe na-arụ ọrụ dị ka e gosiri na ọnụ ọgụgụ ahụ, oghere aka ekpe nke pneumatic cylinder, ya bụ, oghere na-enweghị mkpanaka, na-abanye n'ime ikuku abịakọrọ, na piston ga-aga n'aka nri n'okpuru. omume nke ikuku ikuku, nke mere na nkuku nrụgide α nke mkpanaka hinge ji nwayọọ nwayọọ na-ebelata.Obere, ikuku ikuku na-abawanye site n'akuku mmetụta, na mgbe ahụ ike na-ebunye na lever nke mgbe nile boosting ike lever usoro, ike ga-amụba ọzọ, na-aghọ ike F maka clamping workpiece.Mgbe valvụ nchịkwa ntụziaka dị na ọnọdụ na-arụ ọrụ nke ọnọdụ ziri ezi, oghere mkpara dị na oghere aka nri nke pneumatic cylinder na-abanye n'ime ikuku abịakọrọ, na-akpali piston ka ọ gaa n'aka ekpe, na usoro nkedo na-ahapụ ọrụ ahụ.

Onyonyo 8. Onye na-emegharị pneumatic dị n'ime nke mkpanaka mgbanaka na usoro ihe nkwalite 2 lever

Usoro njigide ikuku nke abụọ

Usoro njigide njedebe ikuku na-eji ike mmịpụta kpụrụ site na nrụgide na-adịghị mma n'ime iko mmiri iji bugharịa ihe ahụ.A na-ejikarị ya ejide iko, akwụkwọ, ígwè na ihe ndị ọzọ nwere nnukwu ọdịdị, oke oke na adịghị ike.Dị ka usoro ọgbọ nrụgide na-adịghị mma si dị, enwere ike kewaa ya n'ụdị ndị a: 1. Ikuku mmiri ara ehi na-ekpochapụ ikuku dị n'ime iko mmiri site n'ike mgbada ala, nke mere na a na-ebute nrụgide na-adịghị mma n'ime iko mmiri, na mmiri ara. a na-emepụta ike ka ọ ṅụọ ihe.Ọ na-eji jide workpieces nwere obere udi, mkpa ọkpụrụkpụ na obere arọ.

Onyonyo 9 Ọdịdị eserese nke squeeze suction cup 2. The ikuku eruba na-ezighị ezi mgbali suction iko valvụ na-efesa ikuku abịakọrọ site na ikuku mgbapụta site na nozzle, na eruba nke ikuku abịakọrọ ga-emepụta a elu-ọsọ jet, nke ga-ewe. pụọ n’ikuku dị n’ime iko mmiri, nke mere na iko mmiri ara dị n’ime iko mmiri.A na-emepụta nrụgide na-adịghị mma n'ime, na nsị nke nrụgide na-adịghị mma na-emepụta nwere ike ime ka ọ ghara ịdị na-arụ ọrụ.

Onyonyo 10 Eserese nhazi nke iko ikuku nrụgide adịghị mma

3. The agụụ mgbapụta iyuzucha iko iko mmiri na-eji electromagnetic akara valvụ jikọọ agụụ mgbapụta na iko mmiri.Mgbe ikuku na-agbapụta, a na-ewepụ ikuku dị n'ime oghere iko mmiri, na-eme ka nrụgide na-adịghị mma ma na-aṅụ ihe ahụ.N'aka nke ọzọ, mgbe valvụ njikwa na-ejikọta iko mmiri na ikuku, iko mmiri ahụ na-efunahụ nsị ma hapụ ọrụ ahụ.

Onyonyo 11 Eserese ihe arụrụ arụ nke iko mgbapụta ikuku ikuku

Usoro njedebe hydraulic atọ

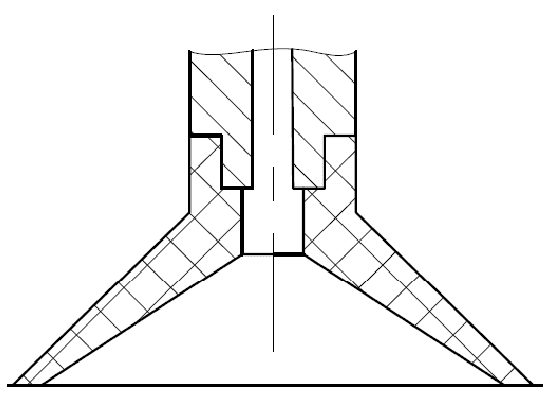

1. Usoro mmechi nke na-emechi emechi: A na-edozi ngwá ọrụ na-egwupụta ihe site na ike dị ike tupu oge opupu ihe ubi ma wepụta ya na hydraulically.Mgbe usoro nkedo na-adịghị arụ ọrụ njide, ọ nọ n'ọnọdụ ịkwanye ngwá ọrụ mkpọpu.Ihe owuwu ya bụ na otu isi iyi ndị a na-akpakọba mbụ na-eme ihe na-eme ka ike na-abawanye dị ka rampụ ma ọ bụ lever, nke mere na oche mwụda na-emegharị axially, na-eme ka slips ahụ na-agagharị radially, ma na-akụchi ngwá ọrụ ịkụ ala;mmanụ dị elu na-abanye n'oche na-amị amị na hydraulic cylinder nke a na-emepụta site na casing na-eme ka mmiri na-ekpo ọkụ, na-eme ka oche na-atụgharị na nkwụsịtụ na-aga n'akụkụ nke ọzọ, na-ahapụ ngwá ọrụ ịkụ ala.2. Usoro njigide na-emepe emepe: Ọ na-anabatakarị ntọhapụ mmiri na mkpị hydraulic, ọ nọkwa n'ọnọdụ ewepụtara mgbe arụghị ọrụ njide.Usoro nchikota na-adabere na ntinye nke hydraulic cylinder iji mepụta ike nkedo, na mbelata nrụgide mmanụ ga-eduga n'ibelata ike nkedo.Ọtụtụ mgbe, a na-etinye mkpọchi hydraulic na arụmọrụ a pụrụ ịdabere na ya na sekit mmanụ iji nọgide na-enwe nrụgide mmanụ.3. Hydraulic tightening clamping method: A na-enweta ma ịtọpụ na nkwụsịtụ site na nrụgide hydraulic.Ọ bụrụ na ntinye mmanụ nke hydraulic cylinders nke dị n'akụkụ abụọ jikọtara ya na mmanụ dị elu, ihe ndị ahụ ga-emechi n'etiti na mmegharị nke piston ahụ, na-amachi ngwá ọrụ na-egwupụta ihe, ma gbanwee Mpịakọta mmanụ mmanụ dị elu, ihe ndị ahụ na-adị. pụọ na etiti ahụ, a na-ahapụkwa ngwá ọrụ ịkụ ala.

4. Compound hydraulic clamping method: Ngwaọrụ a nwere isi hydraulic cylinder na ihe enyemaka hydraulic cylinder, na otu isi iyi diski jikọtara n'akụkụ akụkụ hydraulic hydraulic.Mgbe mmanụ dị elu na-abanye n'ime isi mmiri hydraulic, ọ na-eme ka ihe mgbochi hydraulic cylinder isi na-agagharị, na-agafe na kọlụm dị elu.A na-ebufe ike ahụ na oche na-amị amị n'akụkụ nke hydraulic cylinder inyeaka, a na-agbanyekwu mmiri diski, na oche na-agbagharị;n'otu oge ahụ, oche slip na isi hydraulic cylinder n'akụkụ na-agagharị n'okpuru ọrụ nke ike mmiri, na-ahapụ ngwá ọrụ mkpọpu.

Usoro njigide njedebe magnetik anọ

Kewara n'ime iko mmiri ara eletrik na iko mmiri na-adịgide adịgide.

Igwe ọkụ eletrik bụ ịdọta na ịhapụ ihe ferromagnetic site na ịgbanwuo ma gbanyụọ nke dị ugbu a na eriri igwe, na-emepụta na iwepụ ike magnetik.Iko mmiri ndọta na-adịgide adịgide na-eji ike ndọta nke igwe ndọta na-adịgide adịgide na-adọta ihe ferromagnetic.Ọ na-agbanwe sekit oghere magnetik na iko mmiri site na ịkwaga ihe dịpụrụ adịpụ magnet, iji nweta ebumnuche nke ịdọrọ na ịtọhapụ ihe.Ma ọ bụkwa onye na-aṅụ ara, na ike ịmịnye nke onye na-aṅụ mmanya na-adịgide adịgide adịghị ka nke electromagnetic sucker.

Oge nzipu: Mee-31-2022